MRO Technical Hub > Technical Reference Online > Ethernet

Ethernet

The worldwide defacto standard for business and PC networking

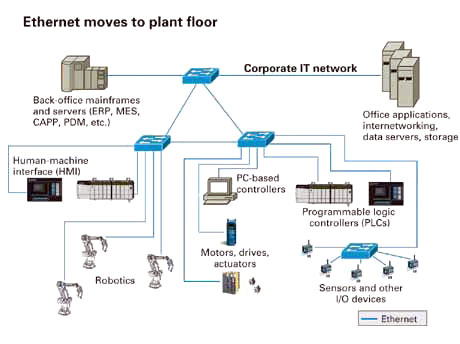

Today, many manufacturing companies maintain separate networks. Over the years, these networks took shape to respond to diverse information flows and control requirements.

The corporate information technology network supports traditional administrative functions such as human resources, accounting, and procurement. This network is based on the ubiquitous Ethernet standard.

The control-level network connects control and monitoring devices including programmable logic controllers, PC-based controllers, I/O racks, and humanmachine interfaces. This network, which has not been Ethernet in the past requires a router or in most cases a gateway to "translate" application-specific protocols to Ethernet-based protocols. This translation allows information to pass between the control network on the factory floor and the corporate network infrastructure, which otherwise are not connected.

The device-level network links the plant floor's I/O devices, such as sensors (transducers, sensors, flowmeters, etc.), and other automation and motion equipment such as robotics, variable frequency drives, and actuators. Interconnectivity among these devices has traditionally been achieved through protocols that have been highly reliable but are somewhat limited in terms of data throughput and interconnectivity with upper-level networks.

Enter industrial Ethernet

Industrial Ethernet provides a more robust solution that lowers costs, boosts productivity, and streamlines system complexity. It is based on an inexpensive and universally deployed data link standard. Ethernet has long been considered an alternative for data transmission on the plant floor. Its acceptance has grown dramatically in recent years thanks to the emergence of impressive reliability. For example, network consortia such as the Open DeviceNet Vendor Association are including details for industrially hardened Ethernet cable systems in their specifications.

While data-oriented networks such as ones used in offices were designed to maximize bandwidth, controland device-level networks were optimized to obtain a very deterministic performance with very low latency. Ethernet's early, collision-oriented implementations made the level of determinism unacceptable on the plant floor.

Today's Ethernet installations (100 Mbps, full duplex in a switched network) show latency measured in microseconds—many orders of magnitude better than most factory floor reliability requirements. A multiple network structure is difficult to justify as current Ethernet implementations meet and/or exceed the throughput, reliability, resilience, and determinism required by the factory floor.

Advantages of ethernet universal, reliable and inexpensive

Ethernet offers several technical advantages. It's fast and its extensive error correction mechanisms endow it with considerable robustness, even in harsh operating environments. It also offers reasonably good security through available encryption mechanisms. Simply put, industrial Ethernet is able to unite a company's administrative, controllevel, and device-level networks into a single system.

Enhanced productivity and efficency

With a more integrated network, mission-critical information can flow freely and in real time throughout the company. As a result, manufacturers experience great gains in collaboration, efficiency, and work quality. In addition, companies may choose to share data from their plant floor process with other business partners, turning their businesses into e-businesses. With an Ethernet network supporting an IP addressing scheme, a company has the ability to collaborate electronically with suppliers, customers, and contractors. The partners can enjoy far better access to certain information such as order status and shipment dates, which they can access in real time right from their own desktops.

Reduced costs

A standard Ethernet interface brings to the factory floor the economies of scale enjoyed today by hundreds of millions of Ethernet users, lowering costs and increasing the number of potential equipment vendors and products for a particular manufacturing application.

Greater bandwidth and overall functionality

Ethernet delivers shared bandwidth far in excess of today's networking systems—typically at full-duplex 10 Mbps to 100 Mbps using switching technologies that can guarantee the throughput to all nodes hooked into the network. An Ethernet network, for instance, allows transmitting detailed control information in real time to a company's ERP system.

Streamlined network structure

A single network eliminates the need to implement, support, and maintain three or more separate systems, reducing overall network costs and improving information access.